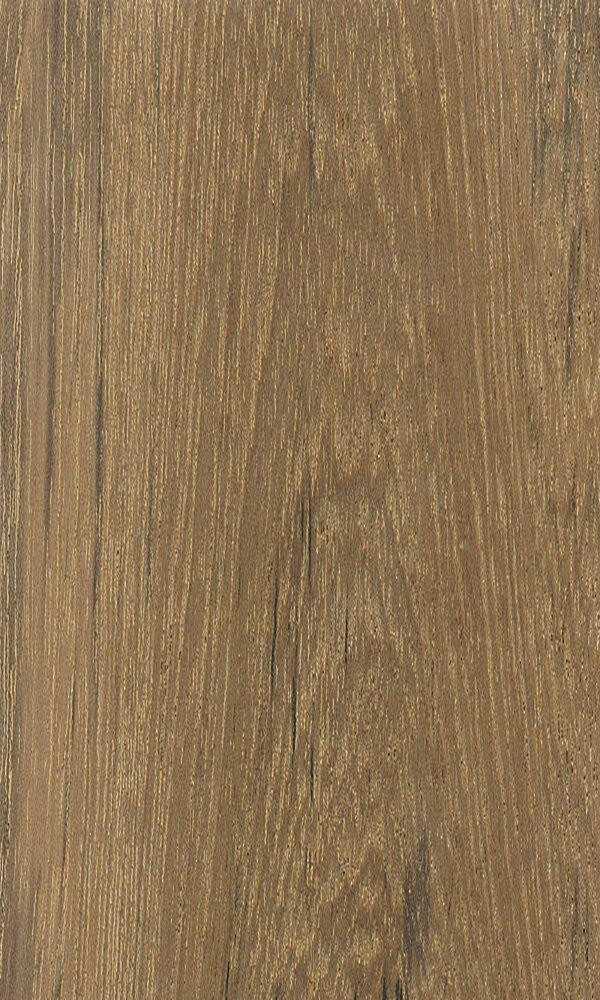

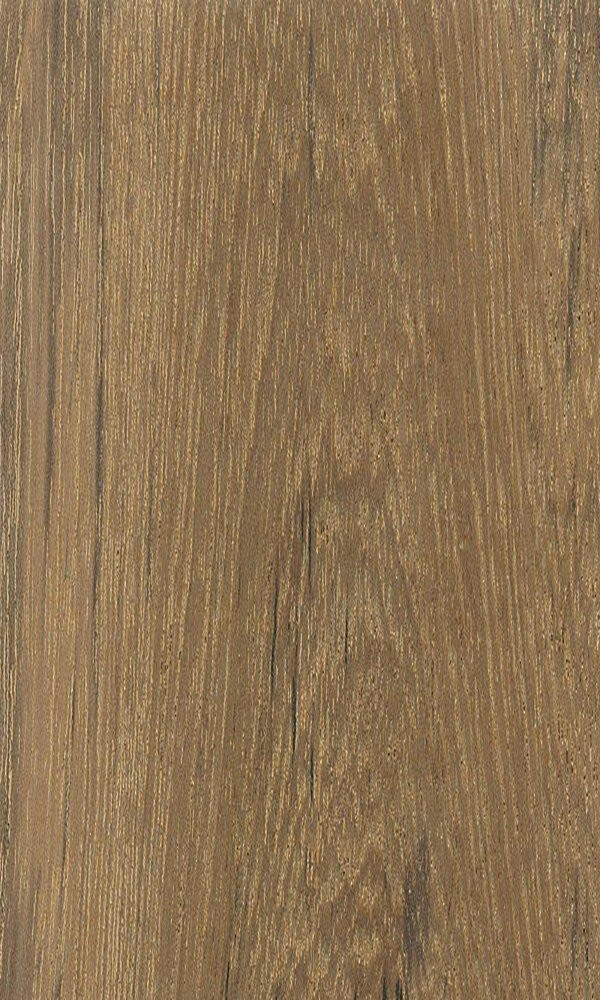

Teak

Teak

Teak (Tectona Grandis) has a coarse uneven texture, is usually straight grained, and has a distinctly oily feel. The heartwood has excellent dimensional stability and a very high degree of natural durability. Although teak is not generally used in the United States where strength is of importance, its properties are similar with U.S. oaks.

GENERAL DESCRIPTION

GENERAL DESCRIPTION

The heartwood varies from yellow-brown to dark golden-brown and eventually turns a rich brown upon exposure to air. Teakwood has a coarse uneven texture, is usually straight grained, and has a distinctly oily feel. The heartwood has excellent dimensional stability and a very high degree of natural durability. Although teak is not generally used in the United States where strength is of importance, its properties are similar with U.S. oaks.

WORKING PROPERTIES

WORKING PROPERTIES

Teak is generally worked with moderate ease with hand and machine tools. However, the presence of silica often dulls tools. Finishing and gluing are satisfactory, although pretreatment is necessary to ensure good bonding of finishes and glues.

PHYSICAL PROPERTIES

PHYSICAL PROPERTIES

Teak is one of the most valuable woods, but its use is limited by scarcity and high cost. Because teak does not cause rust or corrosion when in contact with metal, it is extremely useful in the shipbuilding industry, for tanks and vats, and for fixtures that require high acid resistance.

RATINGS 1 TO 5 (BEST)

RATINGS 1 TO 5 (BEST)

Machining: 4

Nailing: 3

Screwing: 3

Gluing: 2

Finishing: 2

Value-Added Services

ROUGH CUT LUMBER

Rough cut lumber comes straight from the mill through the dry kiln in the form of planks. This is a version of lumber that has been kiln dried with no further processing.

SURFACE 2 SIDES (S2S)

Surfaced Two Sides (S2S) is rough lumber that has been dressed on the top and bottom of the board in order to meet the requested thickness. Associated Hardwoods has state-of-the-art planers that dress the boards to meet the customer's exact specifications.

S2S/RIP-TO-WIDTH

Rip-To-Width lumber is where both sides of the board are ripped to a customer's specified width after surfacing. Also available S3S, straight line ripped one edge after surfacing.

S2S/RIP/CUT-TO-LENGTH

Rip-To-Width/Cut-To-Length is where the board is manufactured and defected to a customer's unique specifications.

S2S/GLUED-TO-SPEC

Glued-To-Spec is where boards are ripped & cut and glued into a panels.

NHLA Grading Rules

The NHLA grades are based on the percentage of clear-defect free wood on a board. The measurements of this percentage are referred to as clear-cuttings.

Other than the FAS grades, the grade of the board is determined from the percentage of these clear cuttings and do not consider defects outside of the clear areas.

Learn more about NHLA Grading with this downloadable resource.

REQUEST A QUOTE TODAY

Complete the form below and one of our sales associates will be in touch with you.