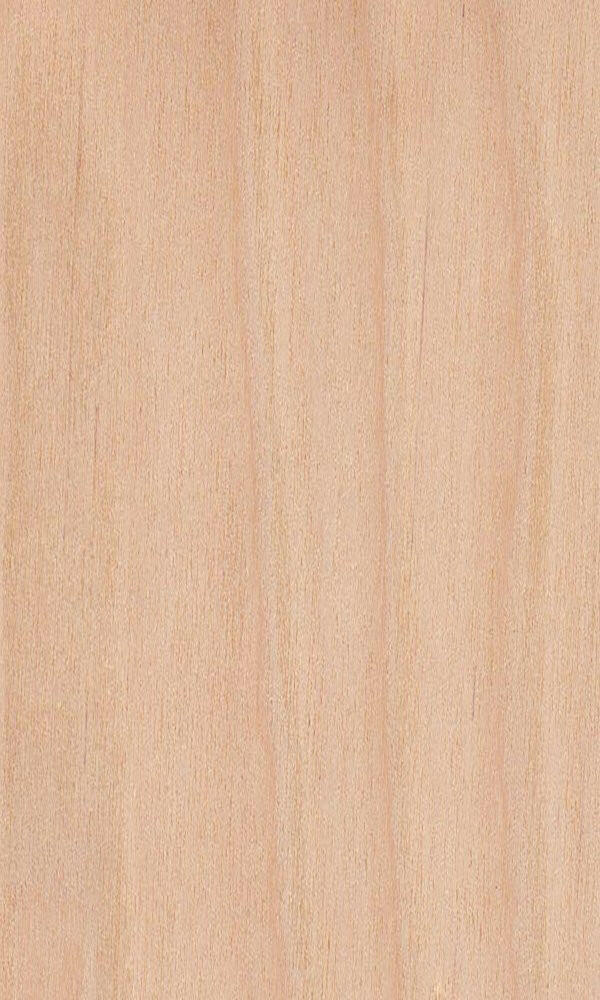

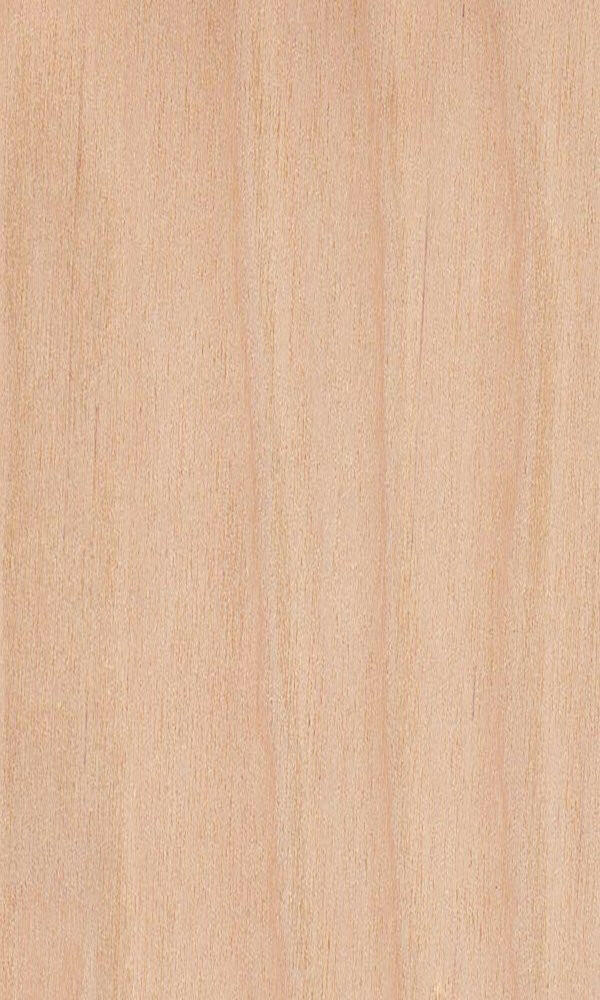

Birch

Birch

Birch wood is known for its durability and natural resistance to rot and decay, making it suitable for both indoor and outdoor applications. The light color of birch wood ranges from creamy white to pale yellow, and it often showcases attractive patterns such as knots and wavy lines. This makes birch a versatile material that can complement a variety of design styles, from traditional to contemporary. It is commonly used for flooring, paneling, trim work, and even musical instruments due to its tonal properties.

GENERAL DESCRIPTION

GENERAL DESCRIPTION

Yellow birch has a white sapwood and light reddish brown heartwood. The wood is generally straight-grained with a fine uniform texture.

WORKING PROPERTIES

WORKING PROPERTIES

The wood works fairly easily, glues well with care, takes stain extremely well, and nails and screws satisfactorily where pre-boring is advised. It dries rather slowly with little degrade, but it has moderately high shrinkage, so is susceptible to movement in performance.

PHYSICAL PROPERTIES

PHYSICAL PROPERTIES

The wood of yellow birch is heavy, hard and strong. It has very good bending properties, with good crushing strength and shock resistance.

RATINGS 1 TO 5 (BEST)

RATINGS 1 TO 5 (BEST)

Machining: 4

Nailing: 3

Screwing: 2

Gluing: 3

Finishing: 5

Value-Added Services

ROUGH CUT LUMBER

Rough cut lumber comes straight from the mill through the dry kiln in the form of planks. This is a version of lumber that has been kiln dried with no further processing.

SURFACE 2 SIDES (S2S)

Surfaced Two Sides (S2S) is rough lumber that has been dressed on the top and bottom of the board in order to meet the requested thickness. Associated Hardwoods has state-of-the-art planers that dress the boards to meet the customer's exact specifications.

S2S/RIP-TO-WIDTH

Rip-To-Width lumber is where both sides of the board are ripped to a customer's specified width after surfacing. Also available S3S, straight line ripped one edge after surfacing.

S2S/RIP/CUT-TO-LENGTH

Rip-To-Width/Cut-To-Length is where the board is manufactured and defected to a customer's unique specifications.

S2S/GLUED-TO-SPEC

Glued-To-Spec is where boards are ripped & cut and glued into a panels.

NHLA Grading Rules

The NHLA grades are based on the percentage of clear-defect free wood on a board. The measurements of this percentage are referred to as clear-cuttings.

Other than the FAS grades, the grade of the board is determined from the percentage of these clear cuttings and do not consider defects outside of the clear areas.

Learn more about NHLA Grading with this downloadable resource.

REQUEST A QUOTE TODAY

Complete the form below and one of our sales associates will be in touch with you.