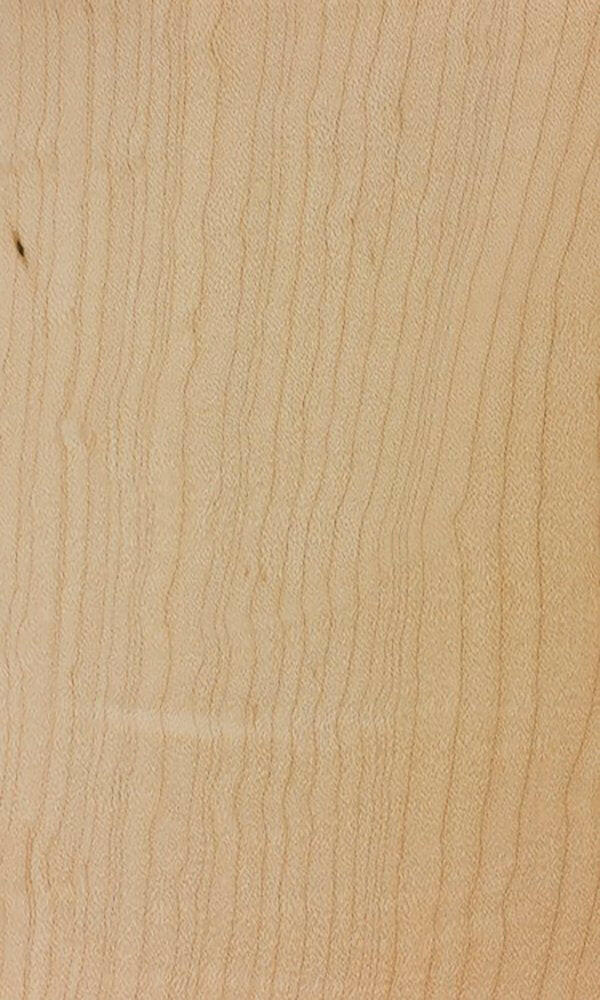

Hard Maple

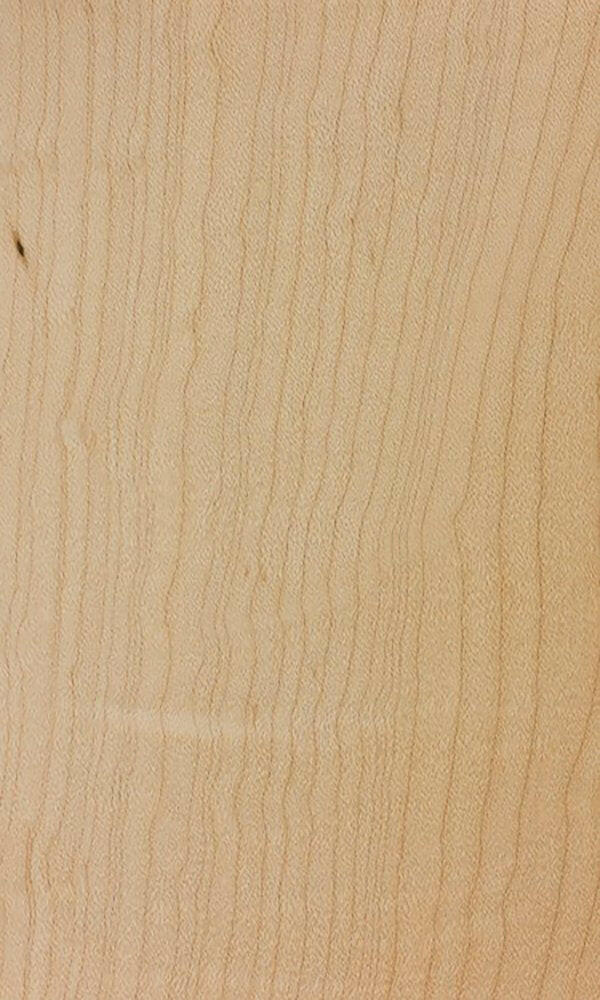

Hard Maple

GENERAL DESCRIPTION

GENERAL DESCRIPTION

The sapwood is creamy white with a slight reddish brown tinge and the heartwood varies from light to dark reddish brown. The amount of darker brown heartwood can vary significantly according to growing region. Both sapwood and heartwood can contain pith fleck. The wood has a close fine texture and is generally straight-grained, but it can also occur as "curly", "fiddleback" and birds-eye" figure.

WORKING PROPERTIES

WORKING PROPERTIES

Hard maple dries slowly with high shrinkage, so it can be susceptible to movement in performance. Pre-boring is recommended when nailing and screwing. With care it machines well, turns well, glues satisfactorily, and can be stained to an outstanding finish.

PHYSICAL PROPERTIES

PHYSICAL PROPERTIES

The wood is hard and heavy with good strength properties, in particular it's high resistance to abrasion and wear. It also has good steam-bending properties.

RATINGS 1 TO 5 (BEST)

RATINGS 1 TO 5 (BEST)

Machining: 4

Nailing: 2

Screwing: 2

Gluing: 4

Finishing: 5

Value-Added Services

ROUGH CUT LUMBER

Rough cut lumber comes straight from the mill through the dry kiln in the form of planks. This is a version of lumber that has been kiln dried with no further processing.

SURFACE 2 SIDES (S2S)

Surfaced Two Sides (S2S) is rough lumber that has been dressed on the top and bottom of the board in order to meet the requested thickness. Associated Hardwoods has state-of-the-art planers that dress the boards to meet the customer's exact specifications.

S2S/RIP-TO-WIDTH

Rip-To-Width lumber is where both sides of the board are ripped to a customer's specified width after surfacing. Also available S3S, straight line ripped one edge after surfacing.

S2S/RIP/CUT-TO-LENGTH

Rip-To-Width/Cut-To-Length is where the board is manufactured and defected to a customer's unique specifications.

S2S/GLUED-TO-SPEC

Glued-To-Spec is where boards are ripped & cut and glued into a panels.

NHLA Grading Rules

The NHLA grades are based on the percentage of clear-defect free wood on a board. The measurements of this percentage are referred to as clear-cuttings.

Other than the FAS grades, the grade of the board is determined from the percentage of these clear cuttings and do not consider defects outside of the clear areas.

Learn more about NHLA Grading with this downloadable resource.

REQUEST A QUOTE TODAY

Complete the form below and one of our sales associates will be in touch with you.